Why lubrication makes a big difference in Total Cost of Ownership

Lubricants make up only a small part of an HD off-road vehicle’s Total Cost of Ownership (TCO), but their impact is significant. The right engine oils, cooling fluids and greases help reduce wear, improve fuel economy and prevent costly downtime. Wolf Oil lubricant expert Johan Van Hove explains how lubrication directly affects TCO.

Managing a heavy-duty off-road fleet is a daily balancing act between operational efficiency and cost control. For fleet managers in agriculture, construction and mining, every saving counts. Yet one area that is often overlooked is lubrication.

According to Johan Van Hove, Senior Technical and Training Manager at Wolf Oil, investing in the proper high-quality lubricants is one of the easiest ways to reduce Total Cost of Ownership (TCO). “The price you pay for lubrication is minimal compared to your overall vehicle expenses,” Johan explains. “But neglecting it can lead to major issues: increased fuel consumption, faster component wear or failure and expensive, unplanned downtime.”

TCO analysis: 1% for maintenance

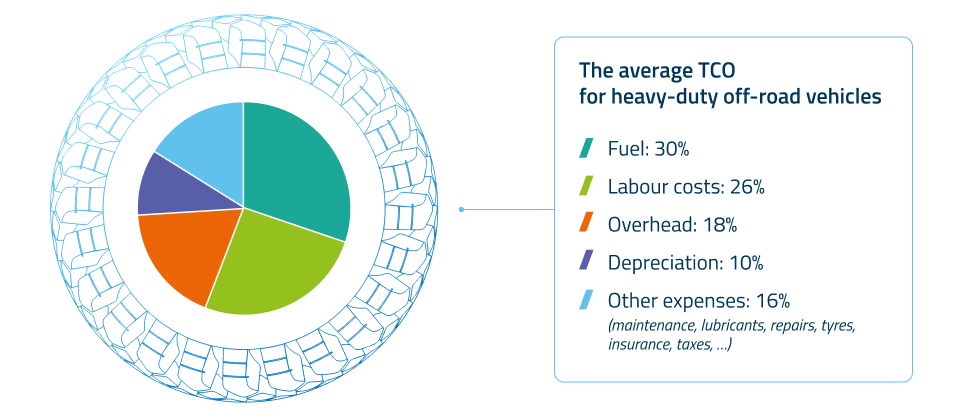

TCO offers a full picture of what it really costs to operate and maintain a vehicle over its lifecycle. Johan breaks down the average TCO for heavy-duty off-road vehicles, like trucks, as follows: “Fuel accounts for the largest share, making up around 30% of the total cost. Labour costs follow closely at 26%, while overhead expenses represent another 18%. Depreciation typically accounts for about 10% of the total. The remaining 16% covers various other expenses, including tyres, insurance, taxes, lubricants, maintenance, and repairs.”

The average TCO for heavy-duty off-road vehicles

|

Within this 16%, maintenance typically represents just 1%, with repair being at around 4%. Lubricants represent only a fraction of that maintenance cost. “Looking purely at the numbers, lubrication seems insignificant,” says Johan. “But poor lubrication decisions often lead to higher fuel usage, accelerated wear and more frequent repairs. Cutting corners on lubricant quality or extending drain intervals always leads to extra unforeseen costs down the road.”

Lubricant cost: a minor investment bringing major benefits

Choosing the correct lubricants has a direct and indirect impact on the following aspects:

- Improved fuel efficiency: reduced friction means less energy loss

- Extended component life: lower wear rates as expensive parts are better protected

- Increasing (up to doubling) maintenance intervals: less downtime and reduced labour costs

- Increased reliability: fewer unexpected breakdowns keep operations running smoothly

- Better job planning: predictable service schedules help avoid production delays

“Downtime in HD off-road situations doesn’t just mean idle machinery,” Johan adds. “It often means crews waiting, missed deadlines and logistical headaches. Proper lubrication management helps avoid that snowball effect of lost time and costs going through the roof.”

Awareness of this issue is still too low. Because lubrication accounts for such a small percentage of the budget, many fleet managers underestimate its impact.

Johan Van Hove

Senior Technical and Training Manager at Wolf Oil

"Unfortunately," Johan continues, "awareness of this issue is still too low. Because lubrication accounts for such a small percentage of the budget, many fleet managers underestimate its impact. On the other hand, they think it is an opportunity to save a few cents per litre on lubrication and fluids. But focusing on short-term savings and neglecting the downstream costs of poor lubrication choices is not advisable. Fleet and maintenance managers should take advantage of talking to experts and invest in proper lubricants that boost productivity and save costs. An oil analysis is key to providing a clear insight into how oil performs in specific conditions."

Want to know more about our oil lab testing services? Discover LubriScan

All lubricants matter, but some matter more!

Some fluids have a more direct impact on operating costs than others. Although it might depend on the specific type of vehicle, Johan gives an average priority ranking:

- Hydraulic oil

- Engine oil

- Driveline fluids

- Coolants

- Greases

- Brake fluids

“Although the above ranking is relevant, one should know that all fluids contribute to equipment reliability and should meet the OEM’s specifications. Cutting corners, even on ‘less critical’ fluids, carries risks. Wolf Oil has a specific offering for HD off-road applications,” adds Johan. “We offer CORS, a complete range for off-road vehicles, covering both STOU oils, engine oils, UTTO oils, driveline fluids, hydraulic oils, greases and coolants. More importantly, we provide expert guidance to help fleet owners match the right product to each vehicle’s requirements. Our digital tool makes it easy to identify the correct lubricant, based on OEM specifications.”

Smoothen the TCO of your heavy-duty off-road fleet: Find the right lubricant

Why lubrication deserves more credit in controlling TCO

As Johan concludes, one of the biggest misconceptions about lubricants, greases and fluids is that they simply reduce friction. “In reality, high-quality lubricants do so much more,” he explains. “They help with cooling, cleaning, corrosion protection, sealing and even noise reduction. The small investment in better lubrication, for example, our CORS range, pays for itself many times over by decreasing fuel usage, protecting components and equipment, preventing unplanned downtime and controlling your TCO. By giving lubrication the attention it deserves, fleet managers can turn one of the smallest cost factors into one of their biggest operational advantages.

The small investment in better lubrication pays for itself many times over by decreasing fuel usage, protecting components and equipment, preventing unplanned downtime and controlling your TCO.

Johan Van Hove

Senior Technical and Training Manager at Wolf Oil

Lower TCO in heavy-duty off-road fleets with smarter lubrication

Get lubricant recommendations that match your needs. Talk to an expert!