What is Total Base Number (TBN) in engine oils and why is it important?

Understanding the Total Base Number (TBN) can be the key to protecting your engine and reducing wear, downtime, and maintenance costs in heavy-duty machinery. Wolf Oil lubricants expert Johan Van Hove explains why the TBN matters more than you think.

The Total Base Number (TBN) in engine oil indicates the extent to which the oil can neutralise acids in fuels. Acids are formed after combustion, and depend on the initial sulphur content in the fuel used, as well as the (in)completeness of the combustion itself. To prevent these acids from damaging the engine and causing corrosion, among other things, it is recommended to use an engine oil with an adequate TBN content. TBN value is indeed a critical value to consider when comparing engine oils.

Johan Van Hove, as Senior Technical and Training Manager at Wolf Oil, explains exactly what TBN is, why it is important, and how best to use it to better protect your heavy machinery used in agriculture and construction and mining.

Poor Total Base Number (TBN) means poor engine protection

To provide a better understanding, Johan explains what TBN actually is, and how it contributes to reliable engine performance. “TBN, or Total Base Number, is a value measured in milligrams of potassium hydroxide per gram of oil (mg KOH/g). It quantifies how much alkaline reserve an engine oil contains to neutralise acids that are present in fuel and formed as a result of fuel combustion. These acids, especially sulphur-derived compounds, can be highly corrosive if not kept under control.”

While TBN is not the only indicator of oil performance, it is a critical one in heavy-duty engine applications. “A typical new engine oil has a Total Base Number ranging from 6 to 13 mg KOH/g. For heavy-duty applications, TBN is usually around 10, and values above 13 can be considered high,” Johan explains. “A higher TBN means more acid-neutralising capacity. This is essential in protecting critical engine parts like pistons, bearings, and liners from acid-induced wear and corrosion, especially in off-road machinery operating under tough conditions.”

A higher TBN means more acid-neutralising capacity. This is essential in protecting critical engine parts, especially in off-road machinery operating under tough conditions.

Johan Van Hove

Senior Technical and Training Manager, Wolf Oil

Total Base Number: a small additive with a big impact

Looking into the average percentage of TBN additives present in engine oil, and its impact on the total cost, Johan explains, “Engine oil is typically composed of two main elements: a base oil (which makes up about 80% of the volume) and specific additives (approximately 20%), depending on the oil type and application.”

“Within that 20%, TBN only represents a fraction of the volume, and it is always part of a performance additive booster pack, which contains other components useful for engine performance. TBN mainly consists of detergents designed to neutralise acids. In terms of cost, this contributes only to a minor fraction of the overall price of the oil. As a result, investing in an oil with sufficient TBN is a relatively low-cost decision that can have a major impact on engine protection and total cost of ownership.”

Investing in an oil with sufficient TBN is a relatively low-cost decision that can have a major impact on engine protection and total cost of ownership.

Johan Van Hove

Senior Technical and Training Manager, Wolf Oil

Causes of TBN depletion in engine oil

“The reason TBN in engine oil declines over time is because it does its job of neutralising acids,” Johan emphasises. “However, the primary driver of TBN depletion is fuel quality, particularly the initial sulphur content in the fuel. Other influencing factors include engine design, injection technology, operating temperature, and continuous or intermittent engine use. As modern fuels contain less and less sulphur, the acid load is significantly lower compared to older fuels, which helps extend the oil’s TBN reserve. Still, in harsh or variable conditions, such as those in agriculture, construction and mining, depletion can occur more quickly than expected.”

When do higher TBN levels deliver maximum value? |

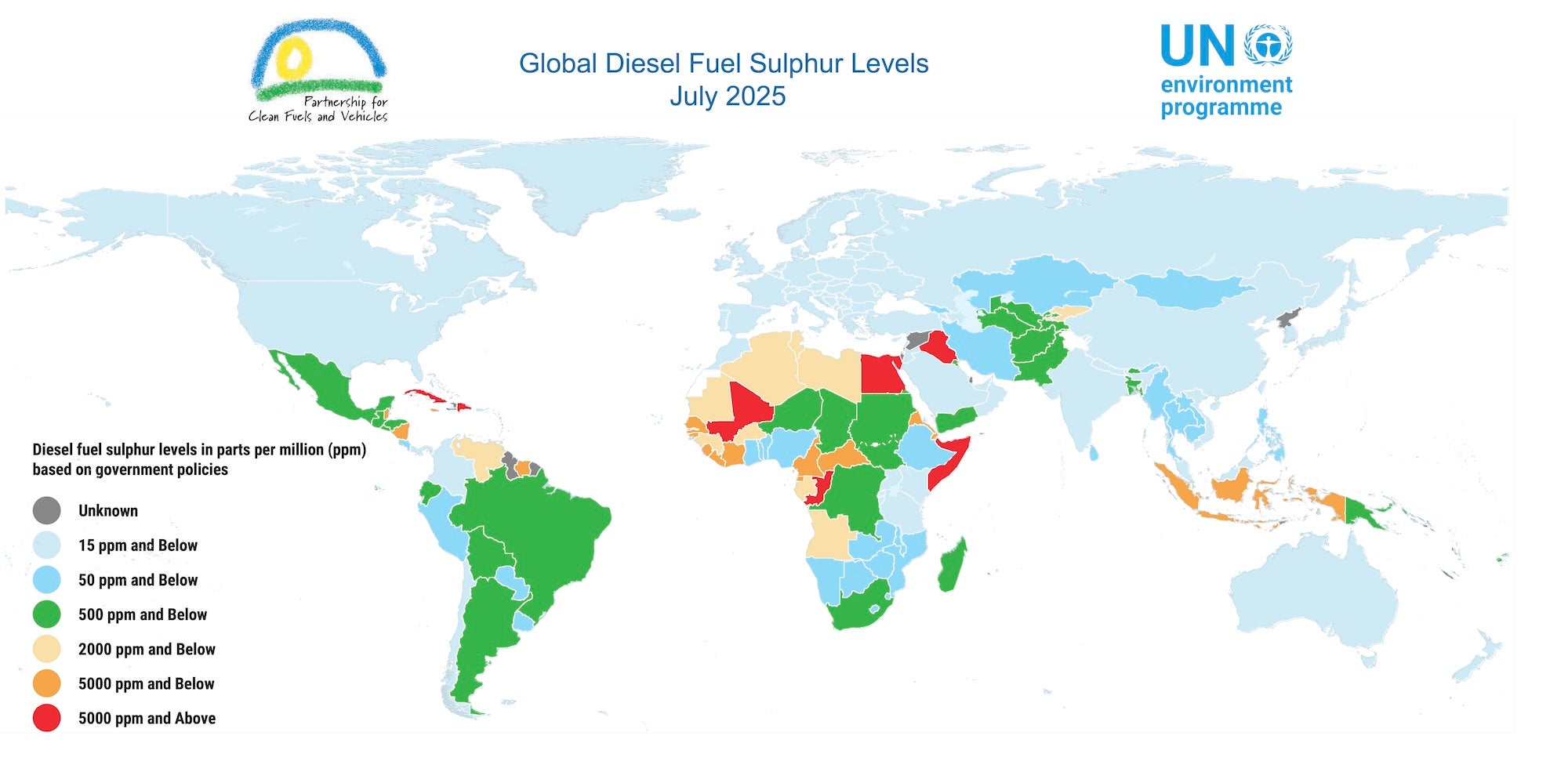

| Higher TBN levels are especially valuable in markets where fuel quality is lower, often with higher sulphur content, such as parts of Africa, Asia, Russia, South America, and the Middle East. They also deliver added protection in regions with long or unpredictable maintenance intervals, like remote mining or agricultural operations in Australia, the Americas, as well as in harsh environments with extreme temperatures or heavy dust. Let’s take a closer look at Africa, where this challenge is particularly visible. The map below clearly shows that many African countries still operate with diesel sulphur levels above 500 ppm, with several even in the 2,000 – 5,000 ppm range. When sulphur burns, it produces acidic by-products that quickly degrade oil and accelerate engine wear. Combine this with high temperatures, dusty environments, and limited access to regular servicing, and the case for higher TBN oils is clear: they are essential to neutralise the excess acids, keep the oil stable, protect against corrosion, and ensure engines continue running reliably between service intervals. |

Source: UN Environmental Program, https://www.unep.org/global-sulphur-levels, 2025 |

TBN monitoring requires lab testing

How to monitor TBN and decide if an oil change is required? “You can't guess it, smell it or judge it by the colour of the oil,” Johan emphasises. “You must measure it through lab analysis. Wolf Oil partners with POLARIS Laboratories®, which uses ASTM D2896 to determine TBN levels accurately. Turnaround time for lab results is typically 1–2 business days. Engine oil should generally be replaced when TBN reaches about 25% of the oil’s original TBN content. This threshold corresponds with what labs define as Severity 3.”

For heavy-duty applications, like agricultural, construction, and mining equipment, Johan recommends oil sampling every 250 to 500 operating hours, depending on load and working conditions (temperature, moisture…). “Regular oil monitoring and oil analysis are the only way to catch early signs of accelerated depletion and avoid unexpected downtime.”

Regular oil monitoring and oil analysis are the only way to catch early signs of accelerated depletion and avoid unexpected downtime.

Johan Van Hove

Senior Technical and Training Manager, Wolf Oil

And what about topping up engine oil with TBN additives? Johan strongly advises against it: “Additive packages in engine oil are carefully balanced. Adding new components to aged oil can cause compatibility issues and may accelerate oil breakdown and compromise engine protection.”

Want to know more about our oil lab testing services? Discover LubriScan

In conclusion: TBN, a number to keep in mind

In conclusion, we can say TBN is a small component of engine oil that has a considerable impact. It may seem like just another lab metric, but it has critical importance in determining engine oil life, protecting engines from wear, and overall fleet cost. With proper oil monitoring and timely oil replacement, fleet managers can reduce unexpected downtime, extend oil drain intervals, and ultimately lower their total cost of ownership.

“If protecting your engines is valuable for your business, TBN is the number 1 parameter to monitor.” Johan Van Hove, Senior Technical and Training Manager, Wolf Oil

Wolf lubricants: higher TBN, stronger protection

With 10 being standard for heavy-duty applications, Wolf goes further. We developed high-performance oils specifically for equipment in agriculture, construction, mining and public works. Thanks to their significantly higher TBN-values, these formulations provide maximum protection in tough conditions and in regions with lower fuel quality:

- Wolf Vitaltech 15W40 Extra (TBN of 15.3 mg KOH/g)

- Wolf CORS 15W40 (TBN of 15.4 mg KOH/g)